Product brief description:

Durable and sturdy

No rust when exposed to water

Standard size

Environmentally friendly and aesthetically pleasing

Complete variety

Wide adaptability

Quality assurance

Material diversity (stainless steel, spring steel, copper, aluminum, alloy steel, etc)

Product specifics:

DIN 128 A Carbon Steel / Galvanizing Curved Spring Lock Washers (1987/1994) series is widely used in mechanical railway industrial products, auto parts, power products, solar products, ships, building decoration engineering, bridges, furniture, home appliances, and other fields.

Product parameter table:

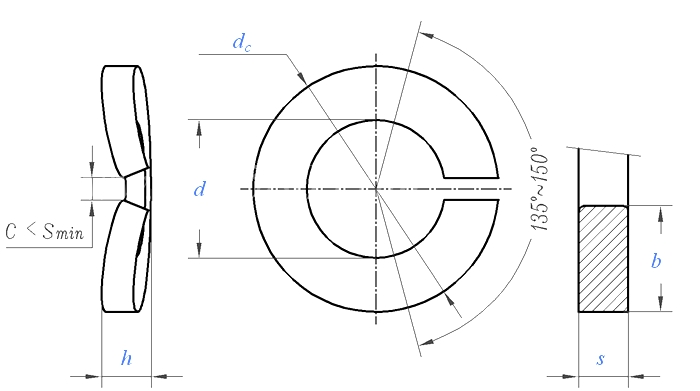

DIN 128 (A) – 1994:

| Nominal Diameter | Φ2 | Φ2.5 | Φ3 | Φ3.5 | Φ4 | Φ5 | Φ6 | Φ7 | Φ8 | Φ10 | |

| d | min | 2.1 | 2.6 | 3.1 | 3.6 | 4.1 | 5.1 | 6.1 | 7.1 | 8.1 | 10.2 |

| max | 2.4 | 2.9 | 3.4 | 3.9 | 4.4 | 5.4 | 6.5 | 7.5 | 8.5 | 10.7 | |

| dc | max | 4.4 | 5.1 | 6.2 | 6.7 | 7.6 | 9.2 | 11.8 | 12.8 | 14.8 | 18.1 |

| b | Nominal Size | 0.9 | 1 | 1.3 | 1.3 | 1.5 | 1.8 | 2.5 | 2.5 | 3 | 3.5 |

| max | 1 | 1.1 | 1.4 | 1.4 | 1.6 | 1.9 | 2.65 | 2.65 | 3.15 | 3.7 | |

| mi | 0.8 | 0.9 | 1.2 | 1.2 | 1.4 | 1.7 | 2.35 | 2.35 | 2.85 | 3.3 | |

| s | Nominal Size | 0.5 | 0.6 | 0.7 | 0.7 | 0.8 | 1 | 1.3 | 1.3 | 1.6 | 1.8 |

| max | 0.6 | 0.7 | 0.8 | 0.8 | 0.9 | 1.1 | 1.4 | 1.4 | 1.7 | 1.9 | |

| min | 0.4 | 0.5 | 0.6 | 0.6 | 0.7 | 0.9 | 1.2 | 1.2 | 1.5 | 1.7 | |

| h | min | 0.7 | 0.9 | 1.1 | 1.1 | 1.2 | 1.5 | 2 | 2 | 2.45 | 2.85 |

| max | 0.9 | 1.1 | 1.3 | 1.3 | 1.4 | 1.7 | 2.2 | 2.2 | 2.75 | 3.15 | |

| per 1000 units ≈ kg | 0.035 | 0.055 | 0.09 | 0.1 | 0.15 | 0.3 | 0.7 | 0.75 | 1.3 | 2.1 | |

| Nominal Diameter | Φ12 | Φ14 | Φ16 | Φ18 | Φ20 | Φ22 | Φ24 | Φ27 | Φ30 | Φ36 | |

| d | min | 12.2 | 14.2 | 16.2 | 18.2 | 20.2 | 22.5 | 24.5 | 27.5 | 30.5 | 36.5 |

| max | 12.7 | 14.7 | 17 | 19 | 21.2 | 23.5 | 25.5 | 28.5 | 31.7 | 37.7 | |

| dc | max | 21.1 | 24.1 | 27.4 | 29.4 | 33.6 | 35.9 | 40 | 43 | 48.2 | 58.2 |

| b | Nominal Size | 4 | 4.5 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 10 |

| max | 4.2 | 4.7 | 5.2 | 5.2 | 6.2 | 6.2 | 7.25 | 7.25 | 8.25 | 10.25 | |

| min | 3.8 | 4.3 | 4.8 | 4.8 | 5.8 | 5.8 | 6.75 | 6.75 | 7.75 | 9.75 | |

| s | Nominal Size | 2.1 | 2.4 | 2.8 | 2.8 | 3.2 | 3.2 | 4 | 4 | 6 | 6 |

| max | 2.25 | 2.55 | 2.95 | 2.95 | 3.4 | 3.4 | 4.2 | 4.2 | 6.2 | 6.2 | |

| min | 1.95 | 2.25 | 2.65 | 2.65 | 3 | 3 | 3.8 | 3.8 | 5.8 | 5.8 | |

| h | min | 3.35 | 3.9 | 4.5 | 4.5 | 5.1 | 5.1 | 6.5 | 6.5 | 9.5 | 10.3 |

| max | 3.65 | 4.3 | 5.1 | 5.1 | 5.9 | 5.9 | 7.5 | 7.5 | 10.5 | 11.3 | |

| per 1000 units ≈ kg | 3.2 | 4.8 | 7 | 7.8 | 12.2 | 13.3 | 21.5 | 23.7 | 42.5 | 68 | |

Material:

DIN 267-26: Spring washer should be made using spring steel (FST) manufacturing compliant DIN 17 221 or DIN 17 222; Spring washer hardness HV430-530